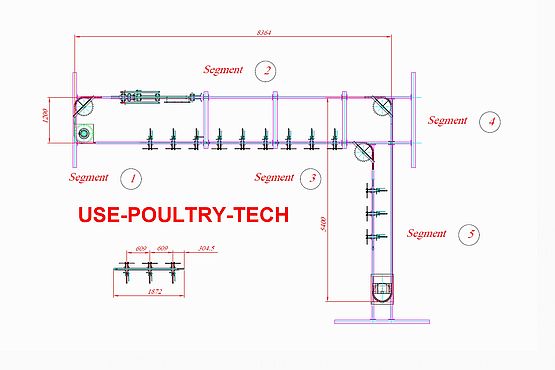

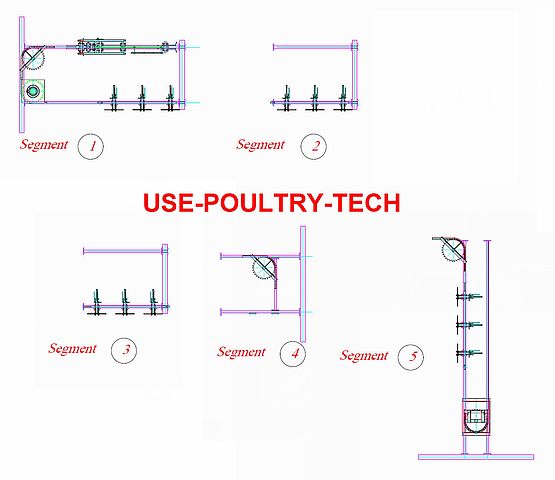

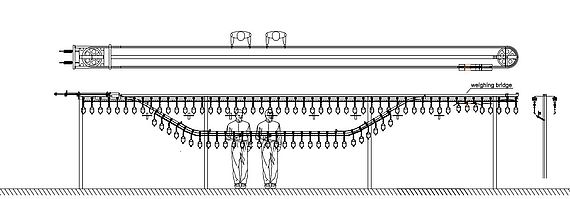

With this weighing line you can meet the demands of your customers by giving them the accuracy they require, in the weight class they want, at minimum costs and minimum give-away. It is also possible to read out the weight of each flock processed (gause curve) to be able to select the farmer that meets your needs. This economically priced weighing line is big in its performance and will pay for itself in no time due to higher earnings and lower costs, it is like a give-away! This line is floor mounted, build sectional, 6 to 20 drop-off stations, fully pre-fab, and can be mounted and installed by your own staff.

Want to know how much money you lose during one year without this line? This line takes control of all your give-aways so you can start making money again, instead of giving it away....

Control panel

The weighing line control panel is PLC based and is ready to be used for the control of the weighing line. Due to the compact hygienic design it is possible to locate the panel close to the line, to keep installation as simple as possible. All connections are pre-wired using standard industrial connectors to make it easy to install. The panel will be equipped with a touch screen to be able to calibrate and service the weighing line. With this design it is possible to control a maximum of 6 to 20 dropping stations, depending on the model selected.

With the available options it is possible to select the configuration you require, the specifications are listed below. If you have additional requirements, please do not hesitate to ask!

Technical specifications:

- Panel: stainless steel.

- Cabinet equipped with the following:

- Main switch, Moeller;

- Power supply 24VDC, Phoenix;

- PLC, Omron, CP series;

- Terminals, Wago, Cage clamp;

- Mounting materials;

- Power specs: 100 - 240VAC 50/60Hz single phase model;

- 380 - 480VAC 50/60Hz three phase model (option);

- Solenoids: 24VDC;

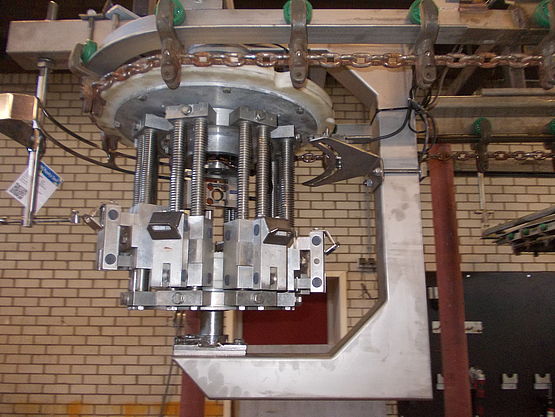

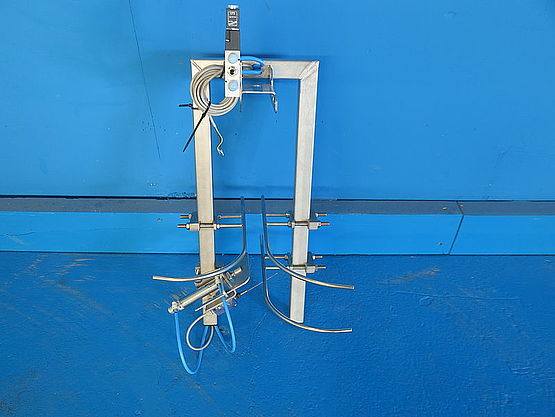

Weighing line standard components:

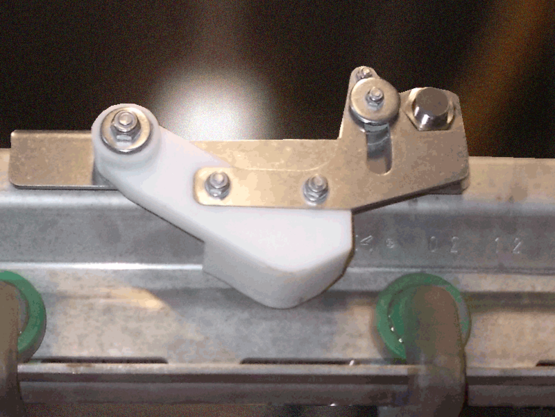

- Trigger sensor Shackle, M30, 24VDC, 3-wire, cable length 5 meter;

- Digital weight-indicator mounted above load-cell, to visually check accuracies of the load cell (when check weight passes);

- Load cell 30KG, 6-wire, cable length 5 meter;

- Passive M12 distributor box, 24VDC, cable length 5 meter;

- Solenoid valves dropping stations, 24VDC, cable length 5 meter;

The following items are available as an option for the ECO weighing lines:

Options:

- Remote Load cell amplifier, mounted in separate panel if the load cell cable is too short. This allows you to increase the distance between the load cell and the weighing line cabinet up to 25 meter (from 5 to 25m);

- B-Trigger sensor, M30, 24VDC, 3-wire, cable length 5 meter. This option for A and B-quality selection;

- Passive M12 distributor box, 24VDC, cable length 10 meter. This option increases the maximum distance possible between the cabinet and the position of the dropping stations;

- Passive M12 distributor box, 24VDC, cable length 15 meter. This increases the maximum distance possible between the cabinet and the position of the dropping stations;

- Receipt Printer, RS232C, paper width 57mm, mounted in the panel door. If there is a need to print the results of the production this receipt printer will do that for you. In the memory the last 10 flocks / production runs will be stored;

- Receipt Printer, RS232C, desktop model, paper width 57mm, cable 5 meter. Specifications identical to door mounted model, only this printer is a desktop model;

- Receipt Printer connection, RS232C, connector inside panel but without printer;

- Line drive frequency controller, single phase model, for regulating the line speed;

- Line drive frequency controller, three phase model, for regulating the line speed;

Interested? Let us quote you.