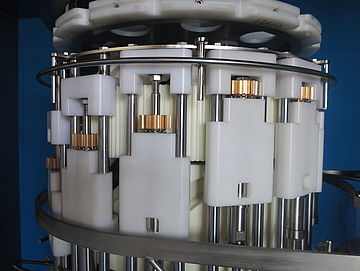

- Specially developed to separate the vent including the bursa from the broiler without causing any damage

- Optimum stretching of the broiler and separation of the bursa

- Minimal maintenance

- The process is completely mechanic and controlled: no vacuum necessary

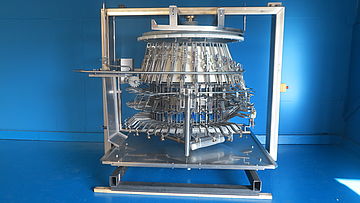

Complete poultry evisceration line 6000 birds per hour

A basic, but complete processing solution for automatic evisceration of up to 6000 birds per hour.

All equipment shown will be supplied new and are build to order. Dutch quality design which ensures a modern, hygienic and safe means to process poultry while at the same time reducing personnel requirements.

Based on proven technology and 30 years of poultry processing experience. Lean engineering, manufacturing and overhead enable a cost-effective processing solution. Low initial investment, low cost of ownership per bird and quick return on investment guaranteed!

The line shown in the movie has a capacity of up to 6000 birds per hour. A smaller capacity line, which can handle up to 4000 birds per hour, is also available as well as bigger capacity machines that can process up to 12000 birds per hour. The automatic evisceration line consists of:

- Vent Cutter, which separates the vent including bursa from the broiler without damage;

- Opener, which provides a clean, exact cut to open the carcass to make room for the eviscerator spoons;

- Eviscerator, which removes the intestines effectivelyand hygienically without the risk of contamination;

- Cropper, which employs drills to remove the crop,oesophagus and trachea;

- Final Inspection, which cleans the abdominal cavity,which allows an effective removal of lungs and other parts;

- Inside/Outside Bird Washer, which cleans the birds on the in- and outside with spray nozzles.

Not shown in the movie below, but also available is an automatic neck breaker / slitter machine.

Product video

Vent Cutter

Opener

- Shear type units are placed in the vent holes

- Shears will open by a guide track

- Small knives placed in the units ensure a straight cut

- Intestines are pressed downwards during the shearing movement to avoid damage

Eviscerator

- Complete removal of the crop and lungs, using improved evisceration units

- The bird remains in the correct position during evisceration by using a centering bracket

- Dual function of the wing clamp: lifts the thighs and holds the bird firmly in position. The spoon removes the complete intestine package

Cropper

- Remaining windpipes and crops are removed by stainless steel drilling units

- Drill driving mechanism with reduced mechanical wear and extended drill life cycle

Neck Breaker

Final Inspection Machine

- Quick removal of remaining impurities in the carcass by vacuum

- Machine is easy to maintain and clean

- Reduced noise level due to special air valve

- Improving shelf life: machine to be placed after the inside outside washer

Inside/Outside Bird Washer

- Thoroughly spray washing the birds both inside and outside

- Wash units are equipped with spray pipes with a spiral high pressure nozzle

- The water supply is controlled by a leakage free automatic control valve

- No water wastage

Automatic evisceration line 6000 bph

Details

| brand: | USE Poultry Tech |

| machine: | Various automatic evisceration machines |

| year manufactured: | Build to order |

| direction: | CW / CCW |

| capacity: | up to 6000 bph |

| current state: | New |