A basic, but complete poultry processing solution. Based on proven technology and 30 years of poultry processing experience. Lean engineering, manufacturing and overhead enable a cost-effective processing solution. Low initial investment, low cost of ownership per bird and quick return on investment guaranteed!

We have designed this line to be very easy to install, operate and maintain.

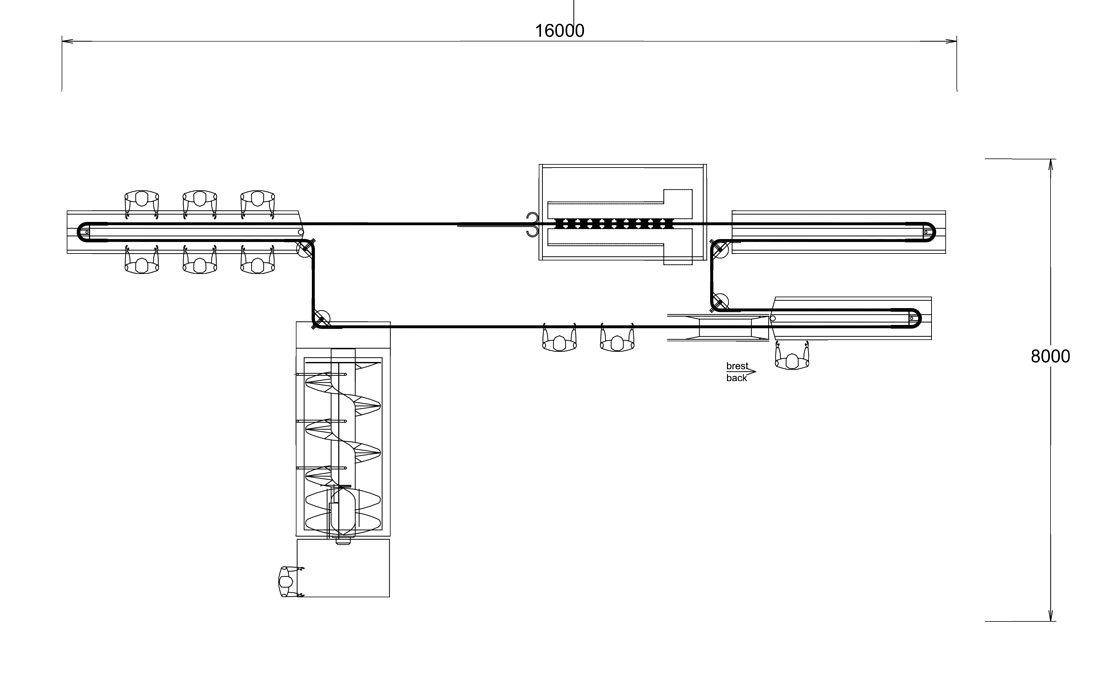

This is a small line to process up to 500 birds per hour. Larger setups are available to process up to 1000, 1500, 2000, 4000 or 6000 birds per hour with the 4000 and 6000 setups including a full automatic evisceration line and other automatic machines.

Equipment shown in the movie include:

- manual hanging and killing area

- bleeding section with blood trough

- hot water scalder

- plucking machine

- head puller

- double-sided evisceration trough

- set of working tools (manual: knives, forks, sharpening steels)

- semi-automatic tools such as a vent cutting pistol, lung suction gun and hock/neck scissor to reduce operator fatigue and increase productivity

- screw chiller

- perforated collection table

All equipment can be supplied NEW. Contact us at sales@use-poultry-tech.com for more information or a quote.